We help you design a custom

SOLUTION

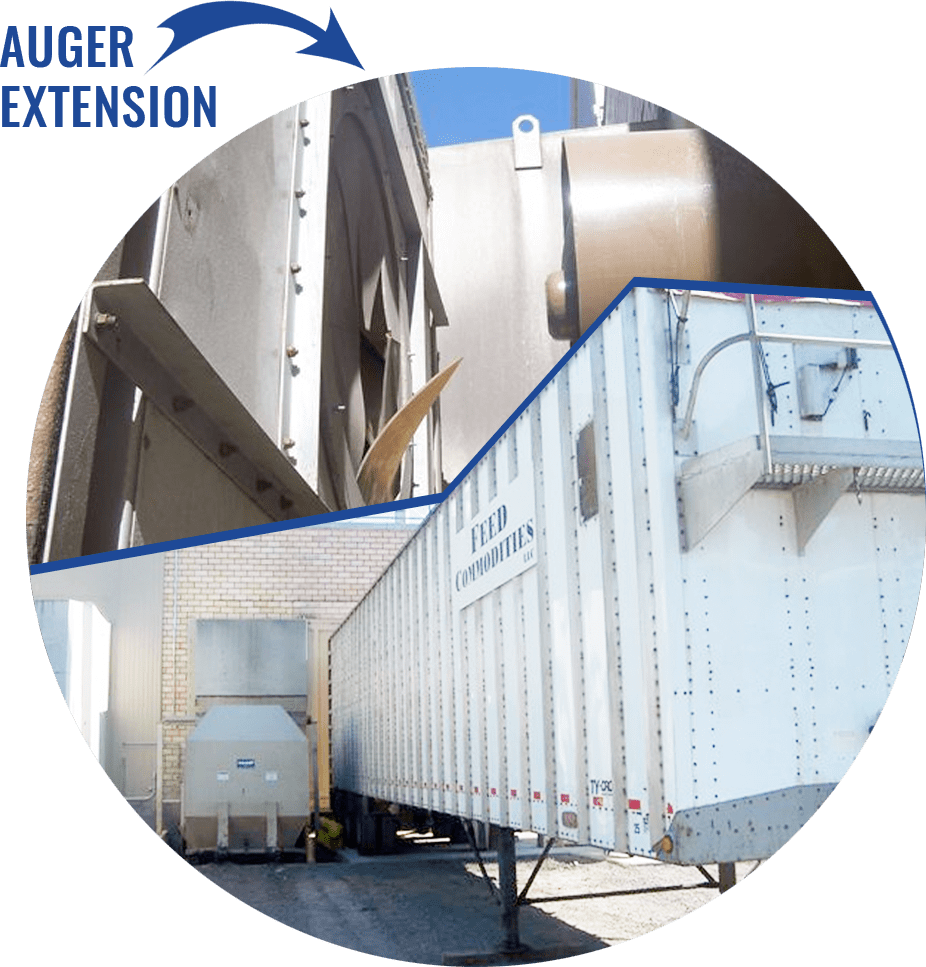

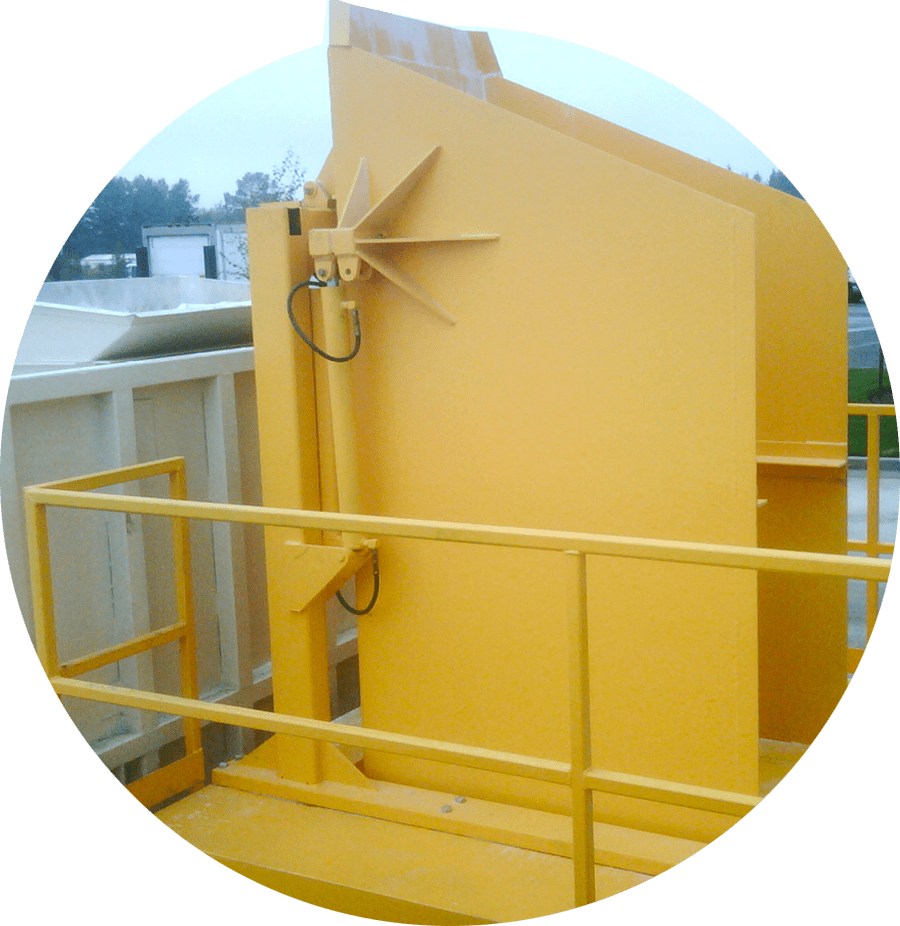

Feed Commodities offers a wide selection of equipment to handle your facility’s needs and objectives. This equipment includes frontloader bins, hydraulic dumpers, chutes, compactors, leveling containers, roll-off containers, trailers, PLC’s, scales and data collection devices and software. This equipment is offered to our customers at no charge, so there are no equipment leasing or rental agreements, nor any maintenance to worry about. Feed Commodities owns the equipment and is responsible for the maintenance of it.

What equipment your facility may require is up to you, and our systems are designed with your objectives in mind. Please review the various equipment descriptions, and let us know how we can help you design the right system for your facility.